When less is more: streamlining telecom inspections

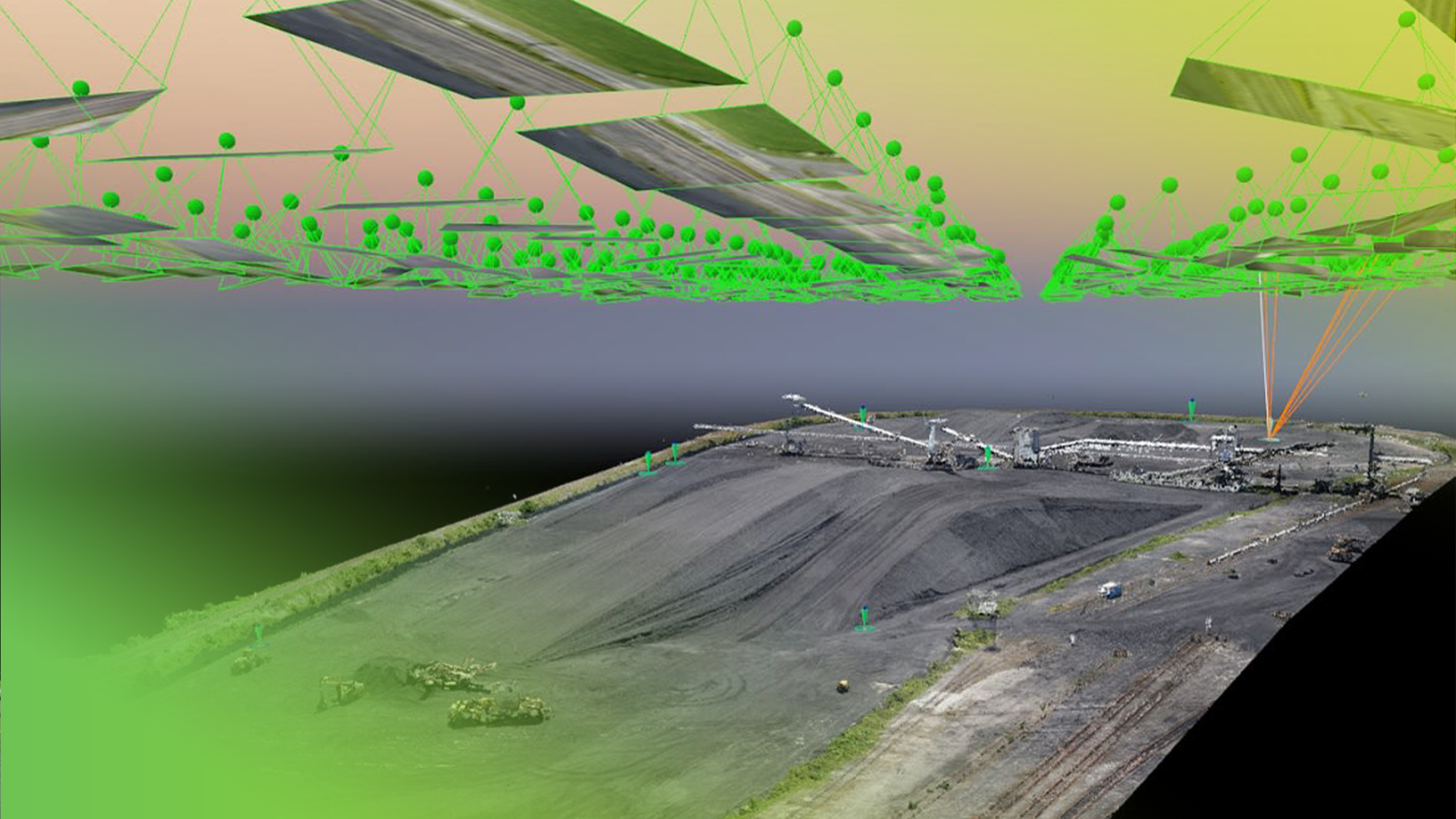

Photogrammetry, the science of measuring from images, begins with gathering photos. There are several methods for doing this - by plane, by drone, by phone - but an agreed-upon feature is that generally, it is easier to get data about a horizontal structure rather than a vertical one. Aerially surveying an open space is easier than surveying tall objects, such as a telecom tower, because you don’t need to gather information from 360 degrees.

The solution to modern telecom inspection

PIX4Dscan and PIX4Dinspect are our answer to this challenge in telecommunication inspections and engineering: a partnership of software that saves time, dangerous climbs, and money. PIX4Dscan is specifically designed to deal with the vertical challenge. It is an app for flight planning that has specific plans and paths for aerially inspecting cell towers which can be adapted according to the site. It automates the flight, meaning even someone with no experience in photogrammetry can plan a successful drone flight for data collection. The result? It cuts time in the field by 75% and dramatically reduces operational costs whilst boosting profitability. It keeps inspection crews on the ground, so the risk of falling from the tower is eliminated.

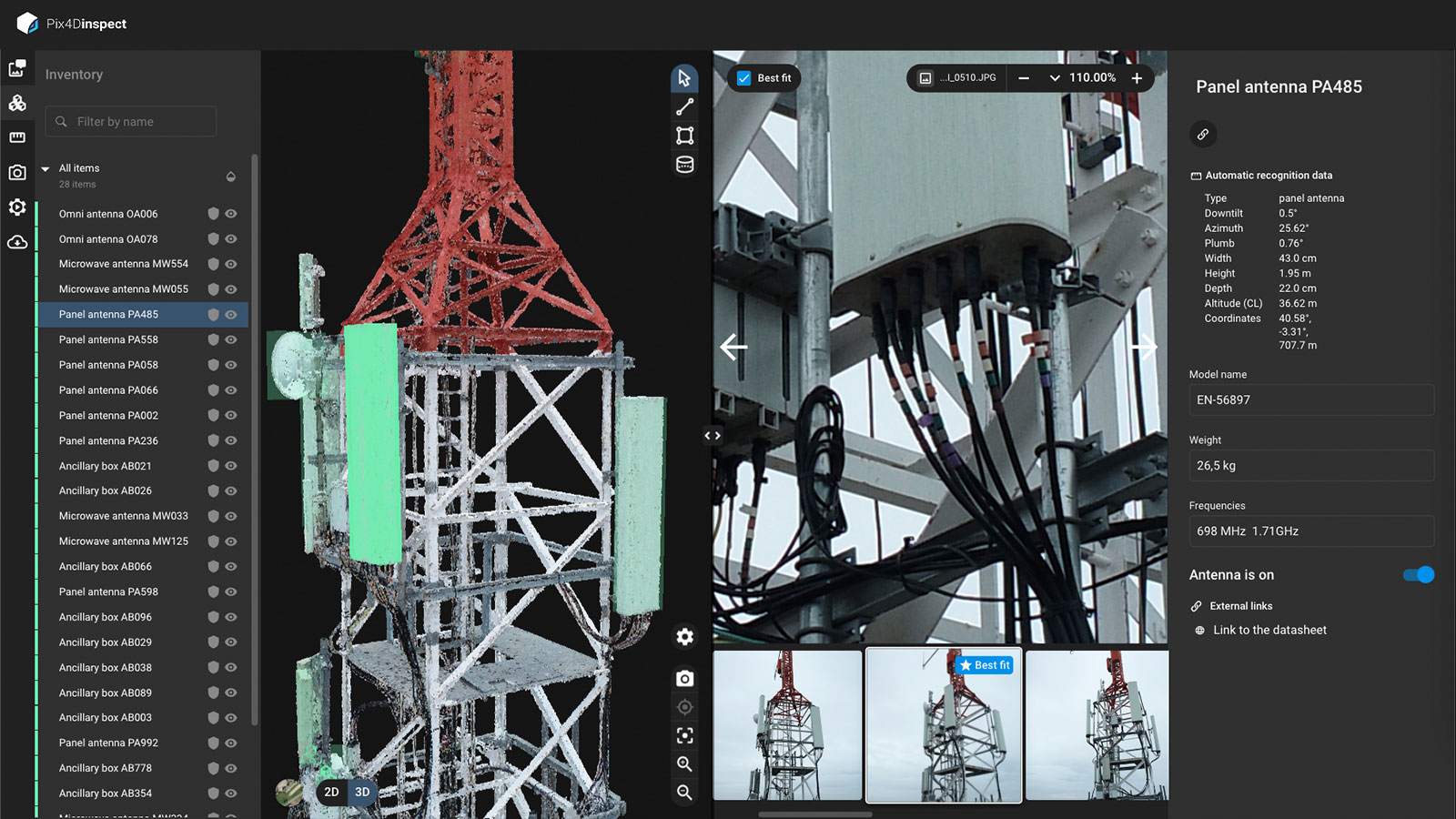

The data is then uploaded to PIX4Dinspect, the cloud-based platform for inspection and asset management. PIX4Dinspect is connected to PIX4Dscan, which allows for seamless integration between both products. Using an internet hotspot means the data can be processed whilst an inspector moves to the next site, saving time. Thanks to being a cloud service, PIX4Dinspect does not require expensive processing hardware, and can handle thousands of assets at the same time using a standard laptop. It processes the images to generate a digital twin of reality and runs over 10 algorithms through the model it creates. These algorithms automatically detect information such as antenna dimensions and angle and simultaneously generate an automatic inventory of the equipment installed. The inspection process is already well underway by the time processing is complete, making work easier for users.

Next generation inspection software

PIX4Dinspect produces image maps, elevations maps, and 3D models (also known as point clouds). This raises the question - why work with 3D models (point clouds) rather than a photorealistic mesh? The answer is simple. Pix4D wants to deliver results with the level of detail that is required of engineers. The best way to do that in this industry is with point clouds. Therefore, a 3D model that looks photorealistic is not necessarily more precise or accurate. The real purpose of the model is to get the best accuracy with a minimal set of images. The accuracy of the point cloud determines its value - rather than focusing on being photorealistic, it is designed to be efficient and accurate.

Once the point cloud is complete, users can inspect the original imagery to identify faults alongside ones that are automatically detected by the software. The 3D model is then annotated by the inspection team, who can share it with colleagues. The people who receive the model will be able to see an intelligent digital twin which includes the original imagery as well as notes made by their co-workers which point out rust, missing equipment, or the space for potential expansion.

The Master cameras

A 3D model that looks realistic is nice but has no use if it does not enable precise and accurate measurements. The challenge is getting the best accuracy from a small number of images to cut down on data collection and processing time. Fewer images required in the field result in lower operational costs and the potential to inspect more towers in a day, which adds to the scalability of PIX4Dinspect. When digital twins first came onto the telecommunications market about 5 years ago, it took between 2,000 and 5,000 images to generate a digital twin. PIX4Dinspect can use just 250.

With those 250 images, PIX4Dinspect has enough data with enough overlap between images to run its AI algorithms through the data with the same level of accuracy as if it was using 2,500 images. However, 250 images can still be a lot - especially with smaller sites that may not need as much information. That’s where the Master cameras tool comes in. This is an AI filtering feature which selects the pictures that cover 100% of the asset and discards ones that are duplicates or not part of that blanket cover. It means that from a set of roughly 400 images, the Master Cameras tool filters through to a core selection - perhaps about 40 - that cover the asset in its entirety. This again saves time, increases efficiency and productivity.

PIX4Dinspect in action

The intelligent digital twins generated by PIX4Dinspect can not only save considerable amounts of time but also provide the necessary data to rapidly determine available space to rent on towers. Carrier and antenna manufacturers can plan their 5G carriers as well as capacity expansions. A review of the digital twins in 2D and 3D can confirm the placement of equipment with detailed measurements.

Telecom companies can easily audit assets with accurate measurements of the tower structures and the equipment. They can avoid return inspections and missing field data as all the necessary information is on the digital twins, and their asset inventory is automatically generated and up-to-date.

Revolutionizing the industry

PIX4Dscan and PIX4Dinspect are already revolutionizing the workflows of clients around the world. In some cases, they are helping drone service providers carry out inspections for Telco companies, whereas in others they are making difficult sites easier to access, such as rooftops. Drones and photogrammetry software are the next step in making inspections faster, safer, and more efficient in terms of time and costs. User-friendly, shareable, and secure, PIX4Dscan and PIX4Dinspect and ready to take your inspection workflow to the next level.