配筋検��査の時間を50%以上削減!スマホスキャンを活用した現場業務の効率化

In railway infrastructure construction, traditional methods for rebar inspection and "as-built" management in reinforced concrete structures have historically been labor-intensive and time-consuming.

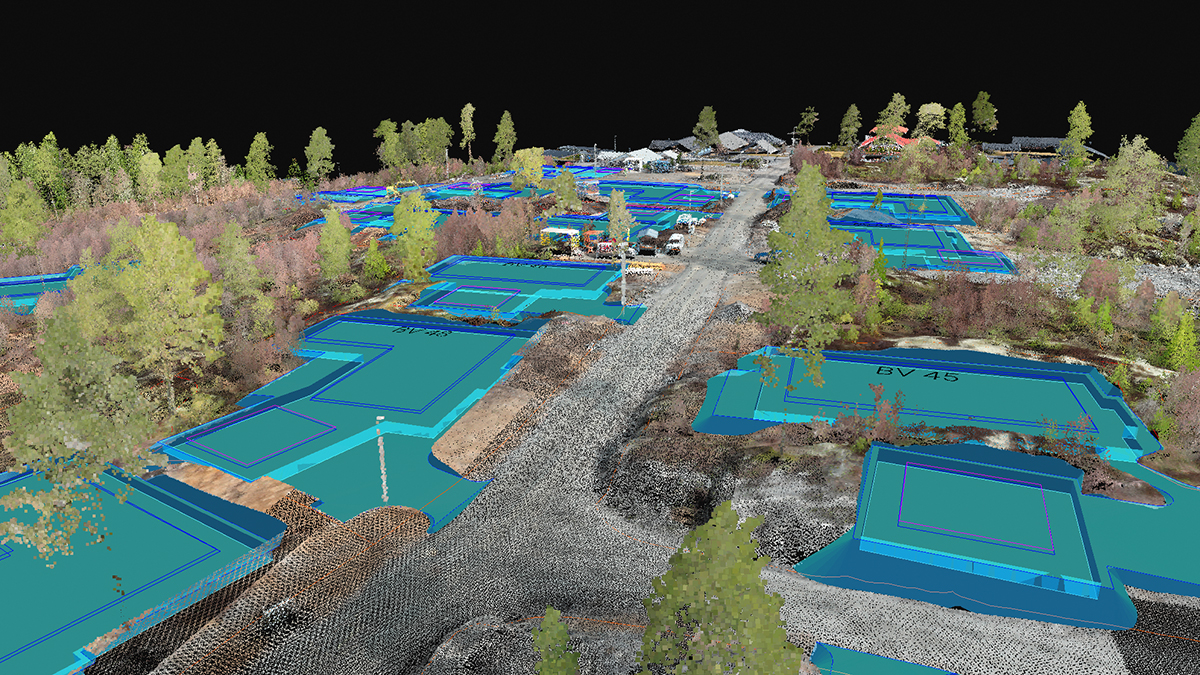

Daitetsu Kogyo Co., Ltd., headquartered in Osaka, successfully streamlined this process during the JR Kansai Main Line elevation project. By integrating the PIX4Dcatch mobile app with Modely (a 3D rebar inspection system by DataLabs), they significantly improved onsite efficiency.

Choosing PIX4Dcatch for rebar inspection

The Civil Engineering Technology Department at Daitetsu Kogyo had long been exploring the potential of smartphone-based 3D measurement. They reportedly tested a wide range of tools in the field, ranging from free apps to premium paid services.

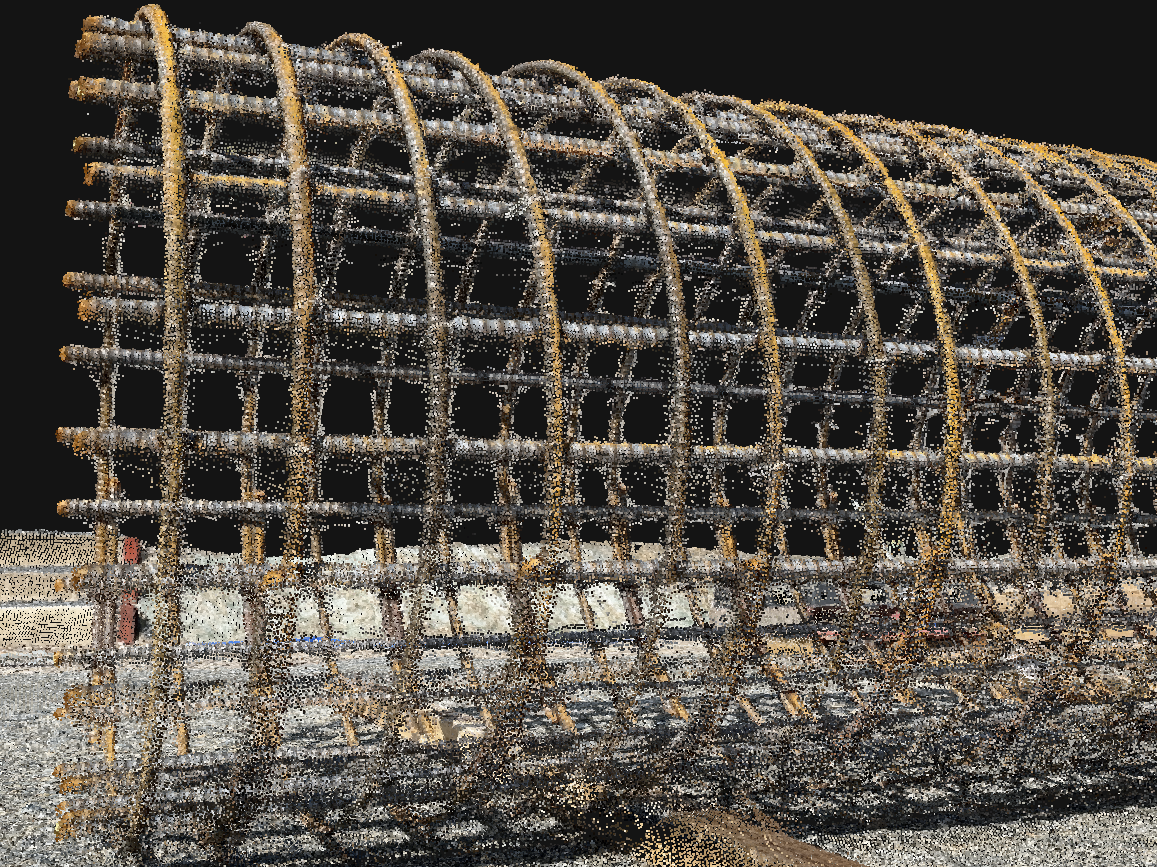

However, measuring rebar presented unique challenges. Many tools struggled to meet professional standards—results were often inconsistent, rebar wasn’t accurately reproduced, or "gaps" appeared in the point cloud data. Finding a solution stable enough for practical, everyday use proved difficult until they implemented PIX4Dcatch.

By utilizing Pix4D’s proprietary technology—which combines photogrammetry with LiDAR—they confirmed the system could capture thin, dark rebar without any data gaps. Furthermore, they found the process produced consistent, reproducible results, regardless of which worker performed the scan.

High-precision measurements without ground control points

Another reason they chose PIX4Dcatch is its ability to capture highly accurate dimensions without the need for ground control points (markers).

Typically, ensuring accuracy in 3D measurement requires setting up markers, but on active jobsites where rebar cages are being assembled in rapid succession, the time required for that preparation was a major hurdle. With PIX4Dcatch, dimensions can be captured markerless, making it easy for even first-time operators to use. By simply walking with an iPhone in hand, a scan can be completed quickly while maintaining dimensional accuracy and point density. This allows rebar inspections to be performed without disrupting the flow of onsite work.

The workflow: rebar inspection with PIX4Dcatch

While PIX4Dcatch makes high-fidelity 3D scanning accessible to anyone on-site, Daitetsu Kogyo took it a step further by integrating the data into their specialized ecosystem. The process was as follows:

- Capture: a worker scanned the rebar cage using PIX4Dcatch on an iPhone Pro.

- Process: Point cloud data automatically generated via PIX4Dcloud.

- Refine: Unnecessary data points (noise) removed to clean up the model.

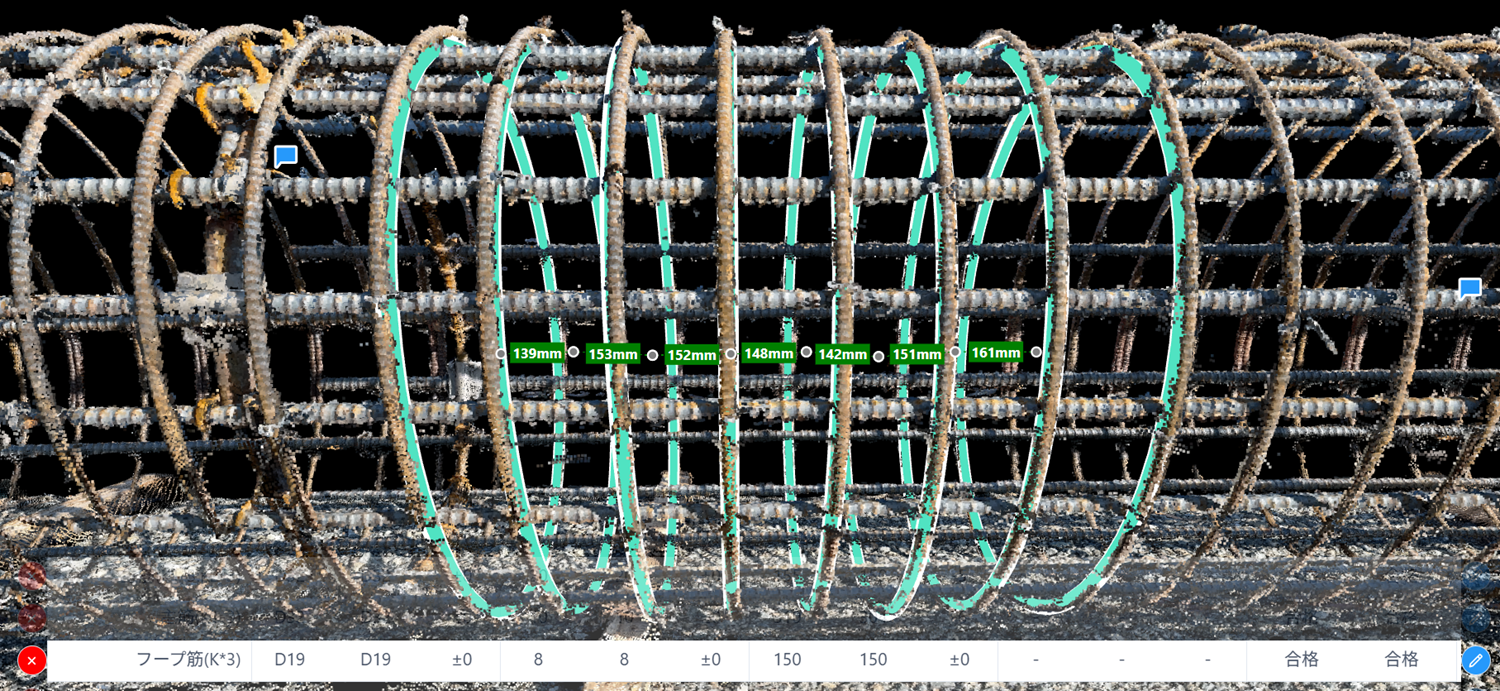

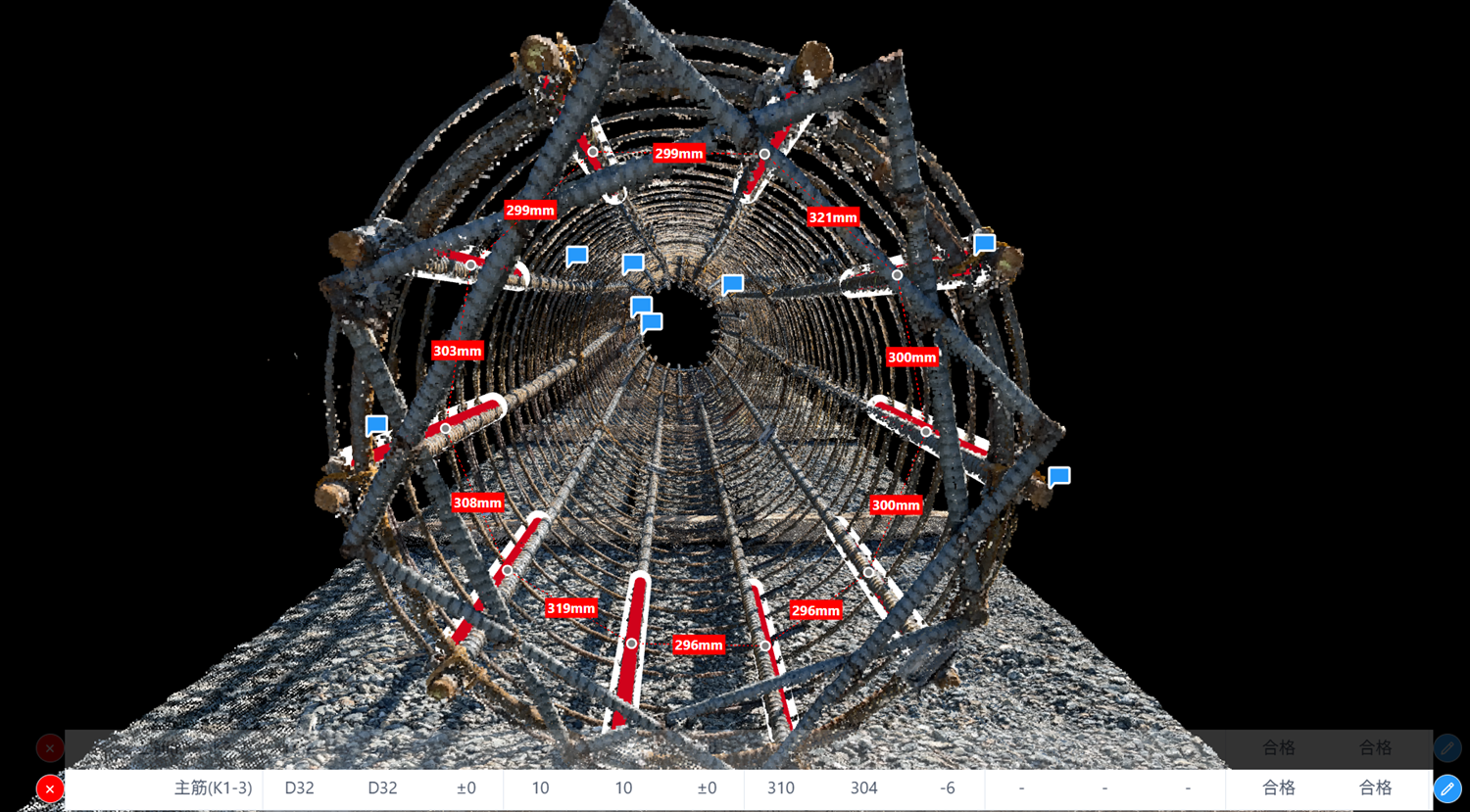

- Analyze: The clean data was imported into Modely, a specialized 3D rebar inspection system, to semi-automate everything from rebar detection to final report generation.

Results: reducing labor time by over 50%

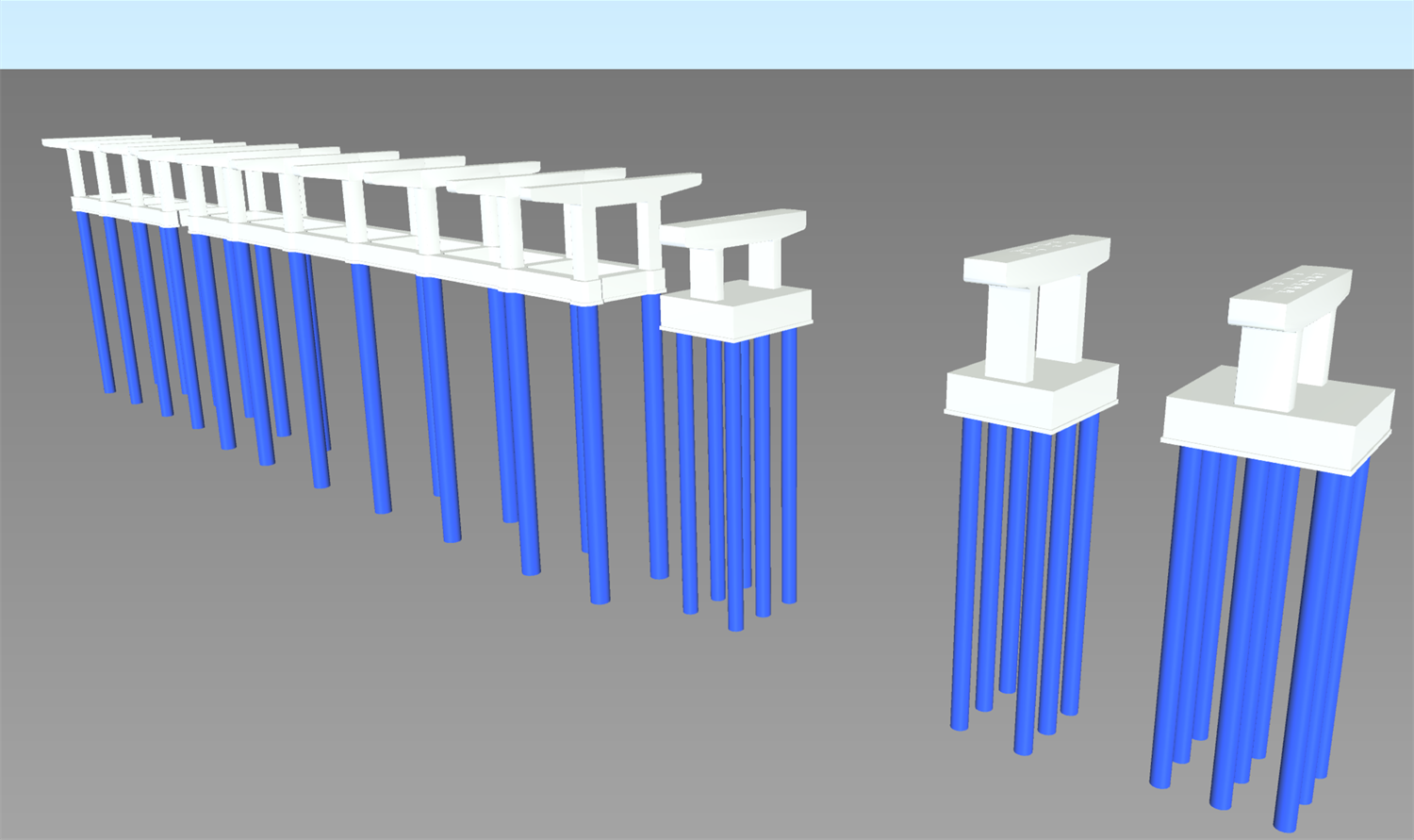

By implementing the PIX4Dcatch and Modely workflow to manage 129 cast-in-place concrete pile rebar cages for the JR Kansai Main Line elevation project, the team achieved the following results:

Number of photos captured:

Before implementation: 81 photos/cage x 129 cages (Total: 10,449 photos) After implementation: 39 photos/cage x 129 cages (Total: 5,031 photos)

Time and labor savings per cage:

Result: 56% reduction in total rebar inspection time per cage Overall Impact: Approximately 850 hours saved (equivalent to 106 man-days)

Under traditional management methods, processes such as photography, measurement, photo organization, and report generation were labor-intensive. The human and time-related costs associated with photo management were particularly high. By replacing most inspection items with a point-cloud management workflow using PIX4Dcatch and Modely, the team successfully reduced the workload per operator by 56%, significantly easing the burden on staff.

The time saved through these efficiencies is now being redirected toward critical onsite tasks, such as enhancing quality and safety management and supporting work-life balance initiatives.

Driving digital transformation in construction

Through the implementation of 3D rebar inspection using a smartphone app, Daitetsu Kogyo has achieved a significant reduction in labor hours and improved onsite operational efficiency. By combining PIX4Dcatch and Modely, they have established a workflow that maintains high precision and reproducibility while keeping pace with the rapid assembly of rebar cages.

This approach is particularly effective for structures with relatively consistent rebar layouts, such as cast-in-place piles. Looking ahead, there are high expectations for expanding this application to more complex rebar geometries and a wider variety of structures.

This article was created with the cooperation of Daitei Kogyo Co., Ltd. and DataLabs Inc.